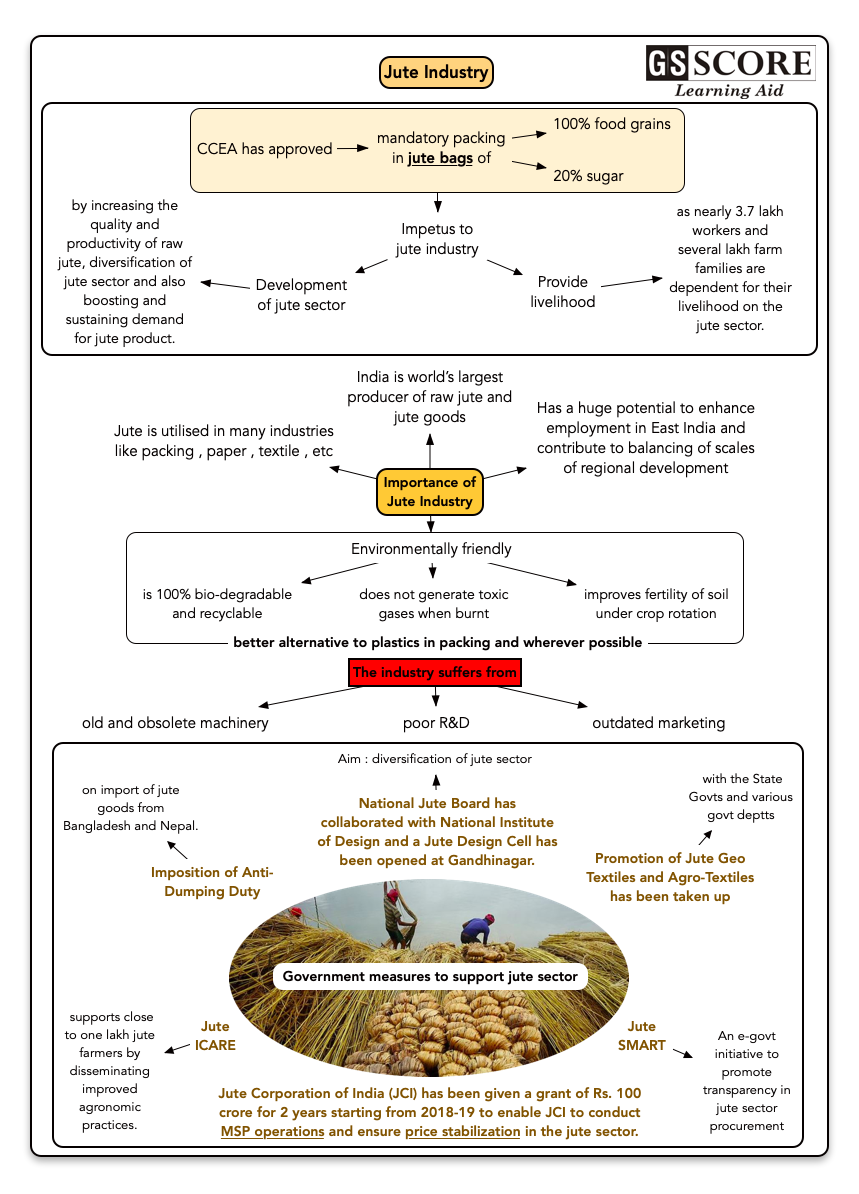

The CCEA approved mandatory packaging of 100% of the food grains and 20% of the sugar in diversified jute bags.

Issue

Context:

- The CCEA approved mandatory packaging of 100% of the food grains and 20% of the sugar in diversified jute bags.

- Initially 10% of the indents of jute bags for packing food grains would be placed through reverse auction on the Gem portal. This will gradually usher in a regime of price discovery.

Background

Jute farming

- The suitable climate for growing jute is a warm and wet climate.

- Temperatures ranging from 25-30 °C and relative humidity of 70%–90% are favorable for successful cultivation.

- Minimum rainfall required for jute cultivation is 1000 mm. It requires 160-200 cm of rainfall weekly with extra needed during the sowing period.

- Soil type : New grey alluvial soil of good depth receiving silt from annual floods is most suitable for jute However, jute is grown widely in sandy looms and clay loams specially river basins.

- PH range between 4.8-5.8 is best for its cultivation so Jute cultivation in red soils may require high dose of manure.

- Plain land or gentle slope or low land is ideal for jute cultivation. In India, Ganga delta region is excellent for jute cultivation as this region has fertile alluvium soil and favorable temperature along with sufficient rainfall. This fertile geographic region is shared by both Bangladesh and India (mainly West Bengal).

- Main jute producing states- The jute crop is grown in nearly 83 districts of seven states - West Bengal , Assam , Orissa , Bihar , Uttar Pradesh , Tripura and Meghalaya . West Bengal alone accounts for over 50 percent raw jute production.

- Main jute producing countries- The leading world's jute producing countries are India, Bangladesh, China and Thailand. India is the world's largest producer of raw jute and jute goods, contributing to over 50 percent and 40 percent respectively of global production.

Uses of Jute

- Originally raw jute was used as a raw material for packaging industries only, later it has emerged as a source of paper industries, textile industries, building and automotive industries, soil saver, decorative and furnishing materials.

- The basic jute products manufactured in jute mills are: Hessian Cloths, Sacking Cloths, Jute Yarn, Carpet Backing Cloths, Bags, Twines, D.W. Tarpaulin/ P.W. canvas, Shopping bags, Geotextiles and Gaps, Jute Mats and floor coverings, Tobacco sheets, Carpets etc.

Analysis of Indian jute industry

Strength:

- Labour intensive industry: It engages approx.4.35 million people.

- Balancing regional development: Jute industry has lot of potential of providing employment especially in East Indian region. The industry offers employment opportunity to 7,500 persons per year, besides more opportunity lie ahead in expansion of existing capacity in new mills.

- Environmental benefits: Jute fibre is 100% bio-degradable and recyclable and thus environmentally friendly. A hectare of jute plants consumes about 15 tonnes of carbon dioxide and releases 11 tonnes of oxygen.

- Fertility of soil: Cultivating jute in crop rotations enriches the fertility of the soil for the next crop. Jute also does not generate toxic gases when burnt.

Weakness:

- Frequent revision of guidelines (to add or dilute items for jute packing) leaves the industry in confusion whether to invest further on the Jute technology development/product development/market expansion or wait for new policies etc.

- Multi unionism is one of the major problems faced by jute industry and engages major concentration of routine management in resolving labour dispute.

- The machinery used in jute industry is old and obsolete with age of machinery ranging between 40 - 150 years. The 150 years old industry with 75% obsolete machinery is tagged as "Sunset industry" with "Vintage machinery".

- Poor Research & Development (R&D) initiation, invention/reverse engineering effort has been grossly neglected in this sector. The reasons for this are lack of farsightedness & forward planning on the part of government and industry.

- Marketing: It has been maintaining a very slow pace in coming out of traditional way of marketing. Indian jute has not been able to build brand image for jute that goes with the quality.

Analysis

Possible impacts of this decision.

- Development of jute sector by increasing the quality and productivity of raw jute, diversification of jute sector and also boosting and sustaining demand for jute product.

- Provide livelihood as nearly 3.7 lakh workers and several lakh farm families are dependent for their livelihood on the jute sectors.

- The jute industry is predominantly dependent on Government sector which purchases jute bags of value of more than Rs. 6,500 crore every year for packing foodgrains.

- Benefit farmers and workers located in the Eastern and North Eastern regions of the country particularly in the states of West Bengal, Bihar, Odisha, Assam, Andhra Pradesh, Meghalaya and Tripura.

Advantages of using Jute fabrics over Polypropylene/Plastic:

- Jute is environment friendly and completely biodegradable, while synthetics possess a number of hazards.

- The toxic effects of synthetics are so serious - both the production and disposal aspects of it - that many western countries have banned it for use in packing of food products.

- Jute bags are indigenously processed products while synthetic bags are manufactured from polyester granules whose manufacture poses a number of hazards.

- The obnoxious gases, particles and volatile organic compounds emitted creates pollution and slow poisons the earth during its disposals.

- Jute bags have porosity, easily withstand the high temperature and are much stronger than poly sacks.

- Jute bags can be recycled, re-used and can be easily repaired.

Reasons behind reducing single use plastics:

- Plastic bags can block waterways and exacerbate natural disasters.

- By clogging sewers and providing breeding grounds for mosquitoes and pests, plastic bags can increase the transmission of vector-borne diseases like malaria.

- High concentrations of plastic materials, particularly plastic bags, have been found blocking the airways and stomachs of hundreds of species.

- Plastic bags are often ingested by turtles and dolphins who mistake them for food. There is evidence that the toxic chemicals added during the manufacture of plastic transfer to animal tissue, eventually entering the human food chain.

- Styrofoam products, which contain carcinogenic chemicals like styrene and benzene, are highly toxic if ingested, damaging the nervous systems, lungs and reproductive organs.

- In poor countries, plastic waste is often burned for heat or cooking, exposing people to toxic emissions. Disposing of plastic waste by burning it in open-air pits releases harmful gases like furan and dioxin.

- Economic damage: Plastic litter in the Asia-Pacific region alone costs its tourism, fishing and shipping industries $1.3 billion per year. Studies suggest that the total economic damage to the world’s marine ecosystem caused by plastic amounts to at least $13 billion every year.

UN Environment has drawn up a 10-step roadmap for governments that are looking for measures to reduce single plastic use.

- Targeting the most problematic single-use plastics by conducting a baseline assessment to identify them, as well as the current causes, extent and impacts of their mismanagement.

- Considering the best actions to tackle the problem, given the country’s socio-economic standing and considering their appropriateness in addressing the specific problems identified.

- Assessing the potential social, economic and environmental impacts of the preferred short-listed instruments/actions.

- Identifying and engaging key stakeholder groups – retailers, consumers, industry representatives, local government, manufacturers, civil society, environmental groups, and tourism associations – to ensure broad buy-in.

- Raising public awareness about the harm caused by single-used plastics by explaining the decision and any punitive measures that will follow.

- Promoting alternatives. Before the ban or levy comes into force, assess the availability of alternatives. Provide economic incentives to encourage the uptake of eco-friendly and fit-for-purpose alternatives that do not cause more harm.

- Providing incentives to industry by introducing tax rebates or other conditions to support its transition.

- Using revenues collected from taxes or levies on single-use plastics to maximize the public good.

- Enforcing the measure chosen effectively, by making clear allocation of roles and responsibilities.

- Monitor and adjust the chosen measure if necessary and update the public on progress.

Government measures to support jute sector

- Jute ICARE supports close to one lakh jute farmers by disseminating improved agronomic practices such as line sowing using seed drills, weed management by using wheel-hoeing and nail-weeders, distribution of quality certified seeds and also providing microbial assisted retting. These interventions have resulted in enhancing the quality and productivity of raw jute and increasing income of jute farmers by Rs. 10,000 per hectare.

- Jute Corporation of India (JCI) has been given a grant of Rs. 100 crore for 2 years starting from 2018-19 to enable JCI to conduct MSP operations and ensure price stabilization in the jute sector.

- With a view to support diversification of jute sector, the National Jute Board has collaborated with National Institute of Design and a Jute Design Cell has been opened at Gandhinagar.

- Promotion of Jute Geo Textiles and Agro-Textiles has been taken up with the State Governments particularly those in the North Eastern region and also with departments such as Ministry of Road Transport and Ministry of Water Resources.

- Government of India has imposed Definitive Anti-Dumping Duty on import of jute goods from Bangladesh and Nepal.

- Jute SMART, an e-governance initiative was launched to promote transparency in jute sector providing an integrated platform for procurement of B-Twill sacking by Government agencies.

- The JCI is transferring 100% funds to jute farmers online for jute procurement under MSP and commercial operations.

Way Forward

There are many opportunities in jute sector

- In many areas Indian Jute industry is ahead of other jute producing and manufacturing countries viz.

- It has learned how to upgrade a lower grade fibre in the batch mix.

- It also leads in diversified value added products.

- Brazil is one of the major importers of Indian Jute, and few of Indian jute bag producers have been awarded zero duty which opens new doors to other industry producers.

Both, Central and respective state governments have pro-jute mindset. They have plans for taking jute industry to new horizon. This is evident from the recent initiative of mandatory packaging.

Industry should accomplish Total Quality Management so as to build quality in the products.

Learning Aid

Practice Question:

Jute is called the golden fiber for its color and high cash value. Critically analyse the rising importance of jute in context of increasing environmental problems and its advantages for India.