Context

NTPC Ltd has invited Expression of Interest to produce torrefied biomass pellets from Indian startups.

About

- It intends to provide a platform to Indian startups to enable them to develop advanced technology for producing torrefied biomass pellets that are well-suited for decentralized small-scale users.

- India produces an estimated 230 Million Metric Tonnes per annum, MMTA of biomass that is either wasted or burnt.

- Biomass co-firing in power plants has proven to be a major solution to cater to this menace thereby reducing carbon footprint in the environment.

- NTPC has been the pioneer in co-firing Biomass in its coal-fired power plants.

Torrefied Biomass Pellet:

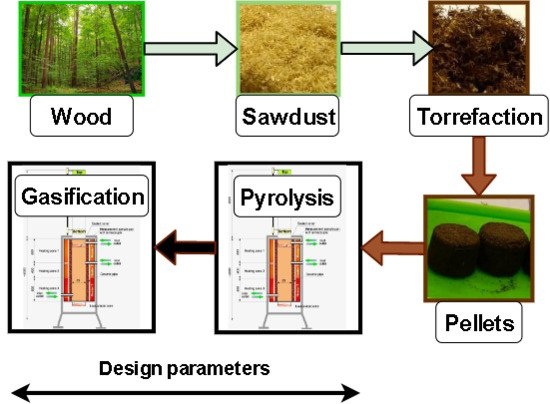

- Torrefied biomass pallets are regarded as one of the most efficient biofuel manufacturing processes to produce the coal substitute known as torrified pellets.

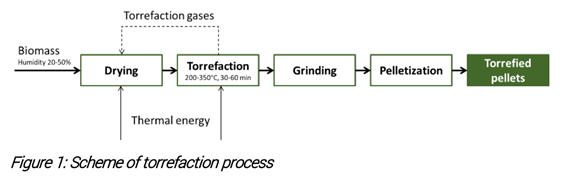

- In the torrefaction process, biomass is processed at the temperature of 250-350°C in the absence of oxygen atmosphere, decomposing the Biomass components, preserving energy content so that the energy density of the torrefied biomass becomes in pellet or briquette form which is much higher than other solid biomasses in trade.

- The properties of the final product depend on the torrefication process and on the kind of feedstock are used.

- Depending on factors such as time, temperature and residence time, the biomass can be torrefied to different torrefaction degrees/temperatures.

- Torrefied biomass pellet production needs to be given importance, as torrefied biomass pellet has more energy density, and its characteristics are closer to coal. Further, torrefied biomass pellets will reduce average transportation costs.

- Benefits:

- Improved combustion properties (Energy content and heating content)

- No biodegradation of the product when stored.

- Increased energy density, significantly low transport cost.

- Increased grind ability, hence requires less energy during processing.

- Reduced Co2 emissions.