Following a plea alleging unscientific handling of fly ash generated by a unit of NTPC, the National Green Tribunal on Monday sought a report from the authorities on the current status on disposal and management of fly ash.

Issue

Context

Following a plea alleging unscientific handling of fly ash generated by a unit of NTPC, the National Green Tribunal on Monday sought a report from the authorities on the current status on disposal and management of fly ash.

BACKGROUND

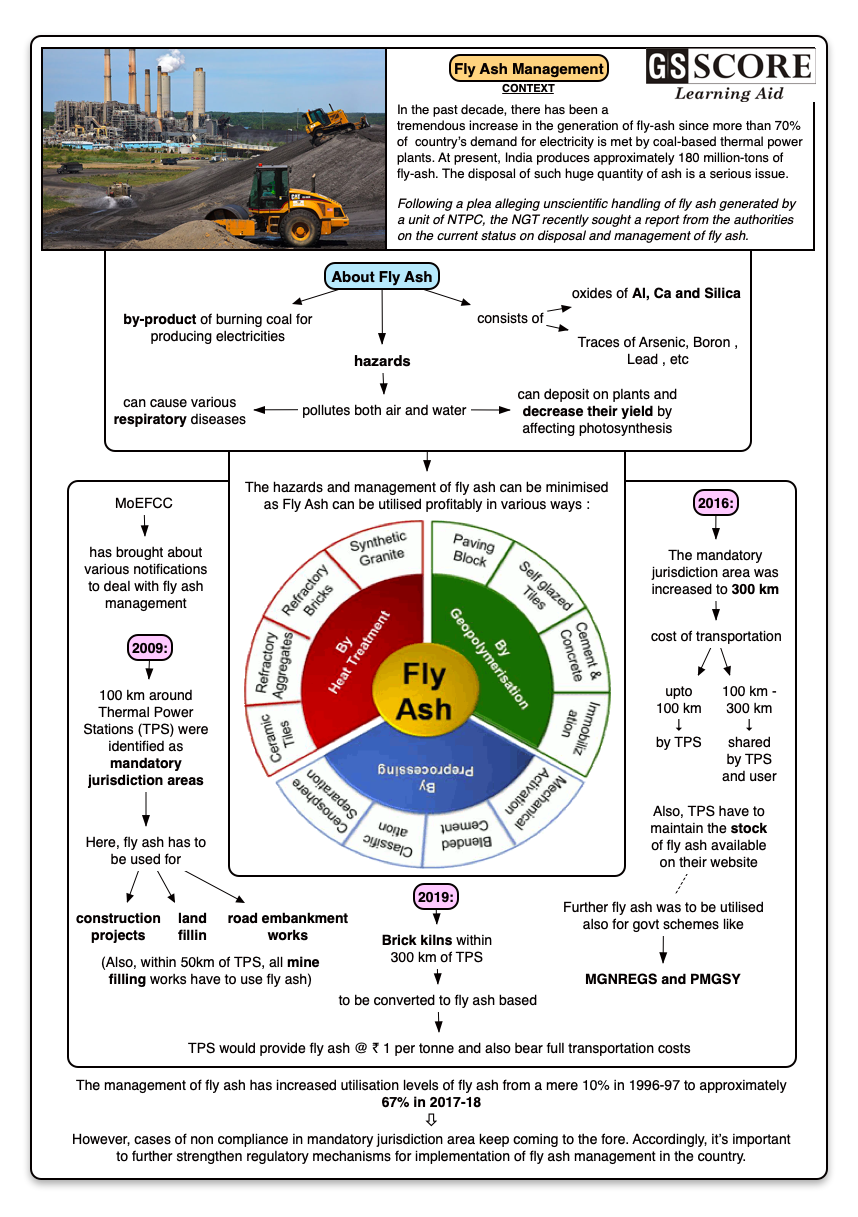

In the past decade, there has been tremendous increase in the generation of fly-ash since more than 70% of country’s demand for electricity is met by coal-based thermal power plants. At present, India produces approximately 180 million-tons of fly-ash. The disposal of such huge quantity of ash is a serious issue.

About Fly Ash

Fly ash is a by-product from burning pulverized coal in electric power generating plants. During combustion, mineral impurities in the coal (clay, feldspar, quartz, and shale) fuse in suspension and float out of the combustion chamber with the exhaust gases. As the fused material rises, it cools and solidifies into spherical glassy particles called fly ash. Fly ash is collected from the exhaust gases by electrostatic precipitators or bag filters.

Fly-Ash Generation in India

The generation of fly ash in India has increased from 68.88 million tonnes in 1996–97 to 163.56 million tonnes in 2012–13. The Ministry of Power, Govt. of India estimates that around 1800 million tonnes of coal will be used every year and 600 million tonnes of fly-ash will be generated by 2031-2032.

Application of Fly Ash

- Cement sector - Fly ash is being currently used by Cement Industries as a pozzolanic material for manufacturing of Portland Pozzolana Cement (PPC). It saves both precious lime stone and coal.

- Mine Filling - Fly ash is being used for backfilling of open cast mines and stowing of underground mines which results in saving of top fertile soil and precious river sand.

- Making Bricks & Tiles - Fly ash is being used in manufacturing of fly ash based building products like bricks, blocks, tiles etc which results in saving of fertile top soil. Fly as based bricks/blocks/tiles are as good as clay based conventional building products in roads & embankments

- Agriculture - Fly ash is being used as manure in agricultural sector as it has many micronutrients. Fly ash provides the uptake of vital nutrients/minerals (Ca, Mg, Fe, Zn, Mo, S and Se) by crops and vegetation, and can be considered as a potential growth improver. It serves as a good fertilizer.

The maximum utilization of fly ash, during the Year 2014-15, to the amount of 42.26 % of total fly ash utilized was in the Cement sector, followed by 13.00 % in mine filling, 11.72 % in making bricks & tiles, 10.77 % in reclamation of low lying area, 9.56 % in ash dyke raising, 3.32 % in roads & embankments, 1.93 % in Agriculture, 0.74 % in Concrete, 0.01 % in Hydro Power Sector & 6.70 % in Others etc (CEA, 2014-15)

Utilization of Fly Ash in India

Out of 160 million tonnes, only 100 million tonnes was utilized. India has achieved a tremendous increase in its utilization from 9.63% in 1996–97 to 61.37% in 2012–13. According to MoEFCC, the fly ash utilisation in the country was 57.63 per cent in 2014 as against 13.51 per cent in 1999.

Benefits of fly ash include:

- Decreased water demand. The replacement of cement by fly ash reduces the water demand for a given slump. When fly ash is used at about 20 percent of the total cementitious, water demand is reduced by approximately 10 percent.

- Reduced heat of hydration: Replacing cement with the same amount of fly ash can reduce the heat of hydration of concrete. This reduction in the heat of hydration does not sacrifice long-term strength gain or durability. The reduced heat of hydration lessens heat rise problems in mass concrete placements.

- Increased ultimate strength: The additional binder produced by the fly ash reaction with available lime allows fly ash concrete to continue to gain strength over time.

- Benefits to Hardened Concrete: One of the primary benefits of fly ash is its reaction with available lime and alkali in concrete, producing additional cementitious compounds.

- Improves the workability of concrete

- Enhances the life of structures and buildings among others

Problems with Fly Ash:

- Longer Setting Time: Compared to cement and water, the chemical reaction between fly ash and calcium hydroxide typically is slower resulting in delayed hardening of the concrete

- Air Content Control: Concrete is susceptible to damage from freeze/thaw cycles if it does not contain air.

- Seasonal Limitations: The winter season is problematic for concrete pouring, and mixtures high in fly ash are even more susceptible to low temperatures.

- Slower Strength Gain: Concrete changes from a liquid to a solid a few hours after pouring, but the curing process may take much longer. It continues to gain strength for weeks after its initial setting period.

Solid Waste Management in India

Solid Waste Management reduces or eliminates the adverse impact on the environment & human health. A number of processes are involved in effectively managing waste for a municipality. These include monitoring, collection, transport, processing, recycling and disposal.

Types of Solid Waste

It can be classified into different types depending on their source:

- Municipal Solid Waste (MSW): It consists of household waste, construction and demolition debris (CnD), sanitation residue, and waste from streets, generated mainly from residential and commercial complexes.

- Industrial Solid Waste (ISW): In a majority of cases it is termed as hazardous waste as they may contain toxic substances, are corrosive, highly inflammable, or react when exposed to certain things e.g. gases.

- Biomedical waste or hospital waste: It is usually infectious waste that may include waste like sharps, soiled waste, disposables, anatomical waste, cultures, discarded medicines, chemical wastes, etc., usually in the form of disposable syringes, swabs, bandages, body fluids, human excreta, etc.

Solid waste management Methods

- Centralised method: This method involves collection of municipal waste from all over the local area and by means of landfilling, dump outside the city/nagar panchayat limits. This process looks at door-to-door collection of solid waste by waste pickers who hand over to the collection team who then discard the collected waste in the landfill. The waste pickers are employees of the Municipal Corporation or Nagar Panchayat. The collection team is generally contracted out by a tendering process.

- De-centralized method: This is a model seen in a few places like Suryapet in Andhra Pradesh and Bangalore in Karnataka. The waste is collected ward-wise and is segregated at source into bio-degradable and non-biodegradable. The biodegradable waste is composted at a nearby facility by different methods of aerobic and anaerobic composting. The non-biodegradable waste is further categorised into paper, plastic, metal and other waste and then further collected by recyclers for up-cycling or down-cycling of products.

Rules and regulations associated with SWM

Under the 74th Constitutional Amendment, Disposal and management of Municipal Solid Waste is one of the 18 functional domains of the Municipal Corporations and Nagar Panchayats. The various rules and regulations for solid waste management are:

- The Bio-Medical Waste (Management And Handling) Rules, 1998

- Municipal Solid Waste (Management And Handling) Rules 2000

- The Plastic Waste (Management And Handling) Rules, 2011

- E-Waste (Management And Handling) Rules, 2011

Government Initiatives

- In 2014 the Swachh Bharat mission, a five-year nationwide cleanup effort for systematic and total waste management was launched.

- Energy-from-waste initiative reduces the volume of waste from disposal also helps in converting the waste into renewable energy and organic manure. The NITI Aayog, as part of the Swachh Bharat Mission, envisages 800 megawatt from WTE plants by 2018-19, which is 10 times the capacity of all the existing WTE plants put together.

- MoEF&CC recently notified the new Solid Waste Management Rules (SWM), 2016.

- The MeitY has developed affordable technologies to recycle valuable materials and plastics in an environmentally sound manner, including two exclusive PCB recycling technologies.

- India has now completely prohibited the import of solid plastic waste by amending the Hazardous Waste (Management & Trans-boundary Movement) Rules.

- Municipal Corporation of Greater Mumbai, is an ICT enabled waste management project called GPS based Vehicle Tracking and Monitoring System (VTMS). The system is a web based automatic vehicle tracking and telemetric fleet management incorporating Global Positioning System (GPS), combined with GPRS/GSM and digital map technology.

- India is a party to the Basel Convention on transboundary movement of hazardous wastes. The Basel Convention aims at controlling and reduction of transboundary movements of hazardous and other wastes.

- Utilization of plastic waste for enhancing the quality of roads and pavements is being carried out at various cities in India.

Problems in SWM in India

- Open Dumping Practice: The current waste management practice in India involves collecting waste from sources through a community collective bin system, after which it gets transported to a low-lying landfill system with intermediate processing of Municipal Solid Waste (MSW). The open dumping practice is leading to various problems like pollution and health hazards. Both surface and groundwater are affected by this; in fact, groundwater is in a critical state.

- Infrastructure for segregation: At present, mixed waste is usually collected and sent to the dump-sites/waste to energy (WtE) plants/compost plants. Effective system of waste segregation is required at appropriate stages i.e. source of waste generation, collection, transportation, processing and disposal.

- Waste from fruit and vegetable markets: There is no in-house treatment of wet waste generated in fruit and vegetable markets including mandis.

- Lack of compliance and enforcement capacities: There is lack of supervisory staff to oversee operations of solid waste management.

- Costly Transportation: Sanitary landfills are the ultimate means of disposal for unutilised municipal solid waste from waste processing facilities and other types of inorganic waste that cannot be reused or recycled. Major limitation of this method is the costly transportation of MSW to far away landfill sites

- E-waste components contain toxic materials and are non-biodegradable which present both occupational and environmental health threats including toxic smoke from recycling processes and leaching from e-waste in landfill into local water tables.

- The solid waste in Indian cities makes it unsuitable for processing operations like incineration , pyrolysis , etc . due to the high percentage of non combustibles and moisture in the waste

Way Forward

- A detailed mapping of waste quantities, generation sources, and the associated characteristics is vital for the implementation of an effective plastic waste management mechanism in cities.

- Proper segregation of waste must be ensured at the source and that the waste goes through different streams of recycling and resource recovery.

- Bio-methanation is a solution for processing biodegradable waste which is also remains underexploited

- Innovative funding mechanisms, incentives, subsidies for bio-based and recycled plastic product development, and other possible sustainable alternative solutions may help expedite the research and innovation capabilities along with market outreach.

- Blending of recycled plastics with fillers and additives will enhance the strength and usability leading to value-added products.

- The government should expand its focus to 5 R (Reduce, Reuse, Recycle, Refuse, and Repair) instead of 3 R (Reduce, Reuse, Recycle ) to reduce load on land filling

Learning Aid