Geography: Human and Economic Geography Part II

MINERAL RESOURCES

- We live during an age of high consumption rates of matter and energy resources.

- Modern industrial nations depend on aluminium, chromium, iron, copper, lead, mercury, zinc, tin and other metals; on materials such as sand, gravel, stone and clay; and on coal, oil, natural gas, uranium and other energy resources.

- The exploitation of mineral resources depends on their occurrence as concentrations, which render them economically viable.

- Such concentrations reflect both crustal and denudation processes that promote the segregation (fractionation) of materials involved in geochemical cycles.

- Mineral resources are formed via different processes.

Ores

- An ore is a rock containing a suffcient proportion of metal to make its extraction an economic proposition.

- For an ore to be mined, it must be economically profitable to do so.

- However, it is important to note that a metalliferous rock that is valueless as a source of a metal at one time may be worthwhile mining some other time.

Origin of Mineral Deposits

In order for a deposit to form, some process or combination of processes must bring about a localized enrichment of one or more minerals. A convenient way to classify mineral deposits is through the principal concentrating process. Minerals become concentrated in five ways:

- Concentration by magmatic processes within a body of igneous rock to form magmatic mineral deposits.

- Concentration by hot, aqueous solutions flowing through fractures and pore spaces in crustal rock to form hydrothermal mineral deposits.

- Concentration by precipitation from lake water or seawater to form sedimentary mineral deposits.

- Concentration by flowing surface water in streams or along the shore to form placer or detrital mineral deposits.

- Concentration by weathering processes from residual mineral deposits.

Types of Minerals

Normally two types of minerals are recognised:

- Metallic Minerals-These minerals contain metal. Iron ore, copper, manganese, nickel, etc. are important examples of metallic minerals. Metallic minerals are further sub-divided into ferrous and non-ferrous minerals.

- Ferrous Minerals-These minerals have iron content. Iron-ore, manganese, chromite, pyrites, tungsten, nickel, cobalt, etc. are important examples of ferrous minerals.

- Non-ferrous Minerals-These minerals do not have iron content. Gold, silver, copper, lead, bauxite, tin, magnesium, etc. are important examples of non-ferrous minerals.

- Non-metallic Minerals -These minerals do not contain metal. Limestone, nitrate, potash, dolomite, mica, gypsum, etc. are important examples of non-metallic minerals. Coal and petroleum are also non-metallic minerals. They are used as fuel and are also known as mineral fuels.

Other Classification of Minerals

- The wide varieties of minerals that have been explored by man for general and commercial purposes to satisfy his needs are classified in to the following groups:

- Industrial metallic minerals: Iron Ore

- Ferroalloy metallic minerals: Manganese, Chromium, Cobalt, Molybdenum Vanadium, Nickel.

- Precious metallic minerals: Gold (Au), Silver (Ag) and Platinum (Pt).

- Non-metallic minerals: Salt, and Tin, Potash, Asbestos, and Sulphur.

- Power Minerals (Mineral fuels): Coal, Petroleum and Natural Gas which are non-metallic minerals derived from vegetable remains

- Other: Uranium

Mineralized Regions

- The injection of metalliferous and other minerals into the earth’s crust is intimately associated with the movement of the plates or slabs of continental rock of which the crust is composed.

- Many of the concentrations of metalliferous ores are thus found in close association either with areas of ancient rock or with areas of recent tectonic movement in the course of which magma rose to the Surface.

Continental Europe

- Continental Europe was formerly endowed with many deposits of the metalliferous minerals, but many are now exhausted and abandoned. Most lay in the belt of ancient rock, which extends from the Meseta (plateau) of Spain, through France and Germany to Czechoslovakia and Poland.

- Lead, zinc and copper remain of some importance. A second highly mineralized region is the ‘shield’ of very old rock, which makes up much of Finland and northern Sweden. Many metalliferous ores are obtained here, but the most important is the high- grade Swedish iron ore.

- Europe also contains extensive deposits of low-grade bedded iron ores. The most extensive and important are those of Lorraine in eastern France and of the Harz region in West Germany.

CIS

- The Ukrainian plateau Ural Mountains and the rocks of the Siberian ‘shield’ are highly mineralized and the CIS has very large reserves of iron ore and of some non-ferrous metals.

Asia

- Metalliferous resources in Asia, outside the Soviet Union, do not appear to be very extensive. China has large reserves of tin and tungsten, Malaya of tin and India of iron ore, but Japan, the most industrialized Asian country, is also one of the least well endowed.

Africa and Australia

- These two landmasses are both made up largely of massifs or shields of hard, ancient rocks, intruded by numerous lodes or ore bodies. Africa, especially south of the Sahara Desert, is richly endowed.

- Among its most important resources are the copper of Zambia and Zaire, the gold and diamonds of South Africa and the tin of Nigeria. But there are also important reserves of chrome, zinc, manganese, cobalt, the radioactive minerals and of bauxite-the ore of aluminium.

- Australia has a number of rich sources of lead-zinc-silver. Its gold mines are no longer of great importance, but Australia is now one of the world’s leading sources of iron ore, much of which is mined in Western Australia and shipped to Japan.

North America

- This is probably the most richly endowed of all the continents, and in none have mineral resources been exploited more actively during the past century. There is today very little active mining in the eastern half of the United States, but there are large reserves of copper, lead, zinc and the alloy metals in the mountainous west.

- In Canada copper, nickel and iron are being worked in the old rocks of the Laurentian Shield,

Latin America

- Gold and silver, which attracted the early explorers, are today of little Importance except in Mexico. Far more important are the copper of Chile, the tin of Bolivia, the bauxite of Guyana, Surinam and some of the West Indian islands, and the iron ores of Venezuela and Brazil.

Industrial Metallic Mineral

Iron Ores (Fe)

Magnetite (Fe3O4):

- Iron content up to 72.4%.

- It is a black mineral formed in igneous or metamorphic rocks in veins or lodes.

- It has excellent magnetic qualities.

Uses: Magnetite iron is used as natural magnets and in electrical industry.

Haematite (Fe2O3):

- Iron content is 70%

- It is most important iron ore.

- They are red ores derived from sedimentary rocks and occur in crystalline or in powdery forms.

- Uses: Iron is most important for the purpose of industrial use.

Limonite (2Fe2O3H 2O):

- Iron content is 60%

- This is brown ore occurring in thick beds in sedimentary rock sequence or in swamps or lakes, (lake or bog iron).

Siderite (FeCo3):

- Iron content up to 48%

- This is ash-grey in colour and is found interbedded with other sedimentary rocks.

- It is basically used for making steel

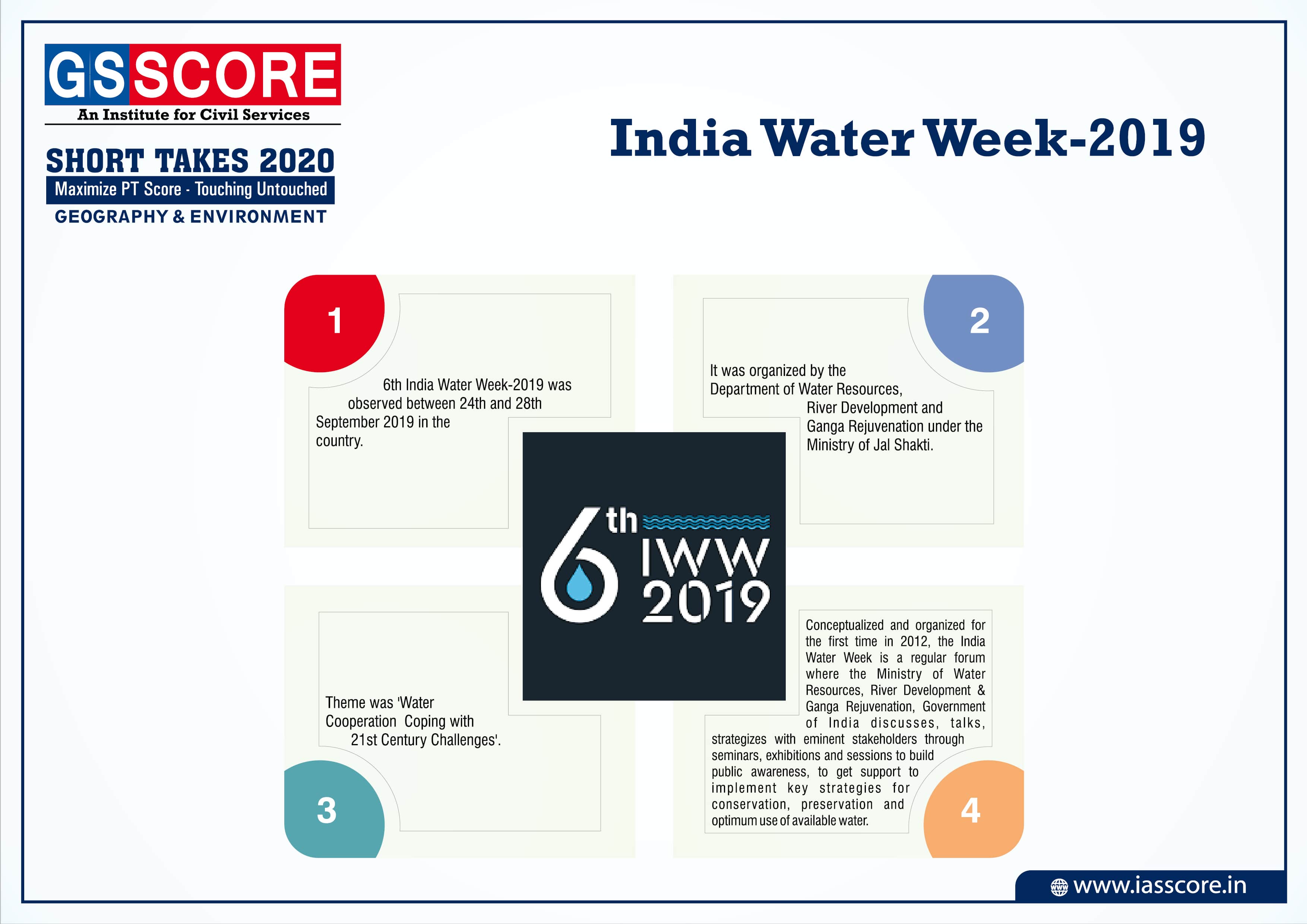

Distribution

- USA

- Lake Superior Region—( Mainly haematite ores) Mesabi Range, Vermilion, Cuyuna, Gogebic, Menominee and Marquette Ranges.

- North-eastern Region—(Mainly Magnetite ores) Adirondacks region of New York and Cornwall area of Pennsylvania.

- South-western Region—(Both haematite and limonite ores) Birmingham and Alabama.

- Western Region— Utah (magnetite), Nevada, Wyoming (haematite) and California.

- Canada— Lake Superior Region, Labrador and Quebec (Haematite), the main centres being Schefferville and Wabush city. Newfoundland, British Columbia.

- CIS — Near Moscow and at Krivoi Rog in the Ukraine (haematite ore); Siberia and the Urals region near Magnitogorsk; Kuzbas at Kustanay. Kursk Magnetic Anomaly—Lipetsk and Donbass.

- Sweden— Kiruna and Gallivare (Magnetite ores);

- Central Sweden—Dannemora and Grangeborg;

- Southern Sweden—Kopparberg.

- France— Lorraine (Siderite ores); Normandy in Pyrenees; and central Massif.

- Britain— Scunthorpe (Siderite ores) and Frodingham.

- Germany— Siegerland.

- Spain— Bilbao, Santander and Oviedo (haematite).

- Norway— Kirkenes.

- Finland— Jussaro in the Ekenas Archipelago.

- Austria— Erzberg (siderite) and Huttenburg in Karnten.

- ErstwhileYugoslavia— North of Sarajevo and Zagreb and Banjalanka.

- China— Manchurian deposits at Anshan, Yangtze valley and in Hopei.

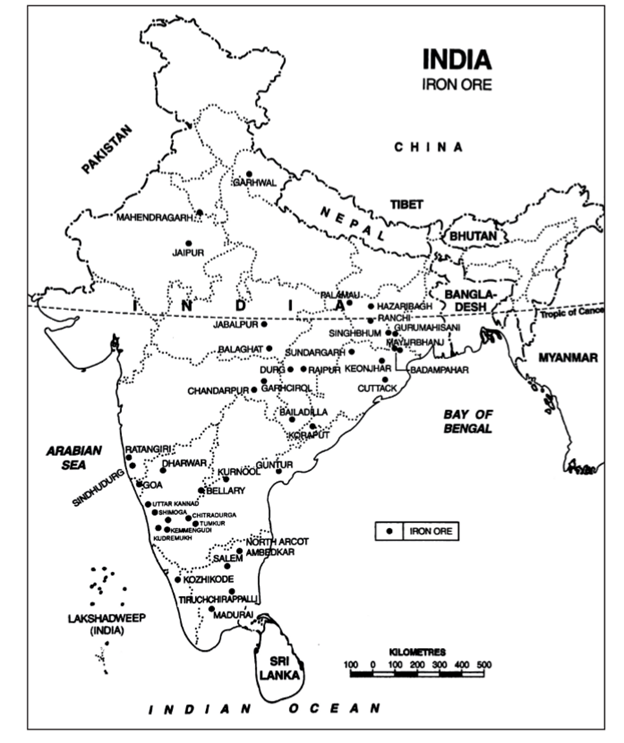

- India— Jharkhand and Orissa.

- South Africa— Postmasburg in Griqualand and Thabazimbi in the Transvaal (haematite).

- Liberia— BomiHtlls and Mt. Nimba.

- Mauritania— Zouerate.

- Australia— Western -Australia at Mt. Goldsworthy, Mt. Whaleback, Mt. Bruce, Mt. Tom Price and Yampi Sound; South Australia at Iron Knob.

- Brazil— Itabira and near Belo Horizonte in Minas Gerais.

- Venezuela— Guiana Highlands at Cerro Bolivar and El Pau.

- Chile— Algarrobo in Central Chile.

- Peru— Nazca-Marcona area.

Chromium (Cr)

Characteristics

Nature: It is a hard, silvery metal with a bluish tinge and a metallic lustre.

Uses:

- Increases the hardenability of steel if mixed along with nickel.

- It is used for making stainless steel which is widely used in manufacture of machinery where steam, water, moist air or acids would corrode ordinary steels quickly.

- Larger amounts, 12-15% increase high temperature strength and corrosion resistance, as well as resistance to wear. Therefore, kitchen utensils, cutlery, oil burner components and bearings are made.

- Chromite ore is also used as a refractory material in basic brick linings of various metallurgical furnaces—chromite or chrome magnesite brick.

- Chromium, used in making nickel-chromium alloys (nichrome), is highly resistant to electric current and is thus used as a safety measure in electric wires, toasters and other electrical appliances.

- Chromium salts and compounds (chromates) are used in the manufacture of paint pigments, chemical industry, for leather tanning, metal and Wood to prevent rotting.

Distribution

- Common Wealth of Independent States (CIS)— Sarany, north of Sverdlovsk and Chromtay in Urals; Balkan countries—Kukas in Albania;

- Philippines—Zambales in northern Luzon;

- Turkey— Fethiye and Guleman; ;

- Africa—Selukwe;

- Zimbabwe—Kildonan; Brazil

- India

Mineral Resources: India

- India is endowed with a rich variety of minerals. It has been estimated that nearly 100 minerals are known to be produced or worked in India, of which nearly 30 may be considered more important including several which although comparatively unimportant in quantity today are capable of material development in future with expansion of industries.

- The country has fairly abundant reserves of coal, iron and mica, adequate supplies of manganese ore, titanium and Aluminum, raw materials for refractories and limestone; but there is a deficiency in ores of copper, lead and zinc.

- There are workable deposits of tin and nickel.” India earns a lot of foreign exchange by exporting a large variety of minerals such as iron ore, titanium, manganese, bauxite, granite and a host of other minerals.

- At the same time India has to depend upon imports to meet her requirements of some other minerals such as copper, silver, nickel, cobalt, zinc, lead, tin, mercury, limestone, platinum, graphite and so many other minerals.

Metallic Minerals

- Metallic minerals form an important section of mining activity in India and provide solid base to metallurgical industries in the country.

Iron Ore

Iron is a metal of universal use. It is the backbone of modem civilization. It is the foundation of our basic industry and is used all over the world. The standard of living of the people of a country is judged by the consumption of iron. Following four varieties of iron ore are generally recognized:

Haematite:

- This is the best quality of iron ore with about 70 per cent metallic content and occurs as massive, hard compact and bumpy ore having reddish or coral red colour.

- Most of the haematite ores are found in Dharwad and Cuddapah rock systems of the peninsular India.

- Over 80 per cent of the hematite ores are concentrated in eastern parts of India comprising of important iron ore producing states of Odisha, Jharkhand, Chhattisgarh and Andhra Pradesh. In the western section, the major concentration is in Karnataka, Maharashtra and Goa.

Magnetite

- Also known as ‘black ore’, due to blackish colour, this is the second best ore, next only to haematite with metallic content varying from 60 to 70 per cent.

- Like hematite, magnetite ores occur in the Dharward and Cuddapah systems of the peninsular India.

- Magnetite ores have magnetic quality as a result of which they are known as magnetite ores. Most of the reserves are found in Karnataka, Andhra Pradesh, Rajasthan, Tamil Nadu and Kerala.

Limonite

- Limonites are inferior ores, yellowish in colour, which contain 40 to 60 per cent iron metal.

- These are found in Damuda series in Raniganj coal field, Garhwal in Uttarakhand, Mirzapur in Uttar Pradesh and Kangra valley of Himachal Pradesh.

- Though poor in quality, these have the advantage of easy and cheap mining.

Siderite:

- Also known as ‘iron carbonate’ this type of iron ore is of inferior quality and contains less than 40 per cent iron.

- It also contains many impurities and its mining is not economically viable.

- However, it is self-fluxing due to presence of lime.

Important Producers

Odisha

- Odisha produces over 40 per cent iron ore of India.

- The most important deposits occur in Sundargarh, Mayurbhanj, Cuttack, Sambalpur, Keonjhar and Koraput districts.

- India’s richest haematite deposits are located in Barabil-Koira valley.

Chhattisgarh

- Chhattisgarh has about 18 per cent of the total iron ore reserves of India.

- This state produced about 18 per cent of the total iron ore production of the country in 201 1-12.

- The iron ores are widely distributed, the prominent deposits being those of Bastar and Durg districts.

- These reserves are of high grade ore, containing over 65 per cent iron.Bailadila in Dakshin Bastar, Dantewada and Bijapur district, and Dalli Rajhara in Durg district are important producers.

Karnataka

- Karnataka is the fifth largest producer and accounts for nearly 8 per cent of the total iron ore produced in India.

- Iron ores are widely distributed in the state, but high grade ore deposits are those of Kemmangundi in Bababudan hills of Chikmagalur district and Sandur and Hospet in Bellary district.

- Most of the ores are high grade haematite and magnetite.

- The other important producing districts are Chitradurga, Uttar Kannad, Shimoga, Dharwar and Tumkur.

Manganese

- It is an important mineral which is used for making iron and steel and it acts as a basic raw material for manufacturing alloy.

- Nearly 6 kilograms of manganese is required for manufacturing one tonnes of steel.

- It is also used for the manufacture of bleaching powder, insecticides, paints, and batteries

Production and Distribution

- India has the second largest manganese ore reserves in the world after Zimbabwe.

- The total reserves of manganese ore as in 2015 are 496 million tonnes.

- The main concentration is in Odisha (44%), Karnataka (22%), Madhya Pradesh (12%), Goa and Maharashtra (7% each), Andhra Pradesh (4%), Jharkhand (2%).

- Rajasthan,Gujarat and West Bengal together share the remaining 2 per cent resources

- India is the world’s fifth largest producer of manganese ore after Brazil, Gabon, South Africa and Australia.

- Maharashtra - The main belt is in Nagpur and Bhandara districts. High grade ore is found in Ratnagiri district also.

- Madhya Pradesh-Maharashtra is closely followed by Madhya Pradesh. The state produced only 11 per cent of India’s manganese ore just two decades ago. The main belt extends in Balaghat and Chhindwara districts. It is just an extension of the Nagpur- Bhandara belt of Maharashtra.

- Odisha-It is obtained from Gondite deposits in Sundargarh district and Kodurite and Khondolite deposits in Kalahandi and Koraput Districts. Manganese is also mined from the lateritic deposits in Bolangir and Sambalpur districts.

- Andhra Pradesh - The main belt is found between Srikakulam and Vishakhapatnam districts. Srikakulam district has the distinction of being the earliest producer (1892) of manganese ore in India. Cuddapah, Vijayanagaram and Guntur are other producing districts.

- Karnataka-The main deposits occur in Uttara Kannada, Shimoga, Bellary, Chitradurg and Tumkur districts

- Other producers- Jharkhand, Rajasthan, Goa, Panchmahals and Vadodara in Gujarat, Udaipur and Banswara in Rajasthan and Singhbhum and Dhanbad districts in Jharkhand are other producers of manganese.

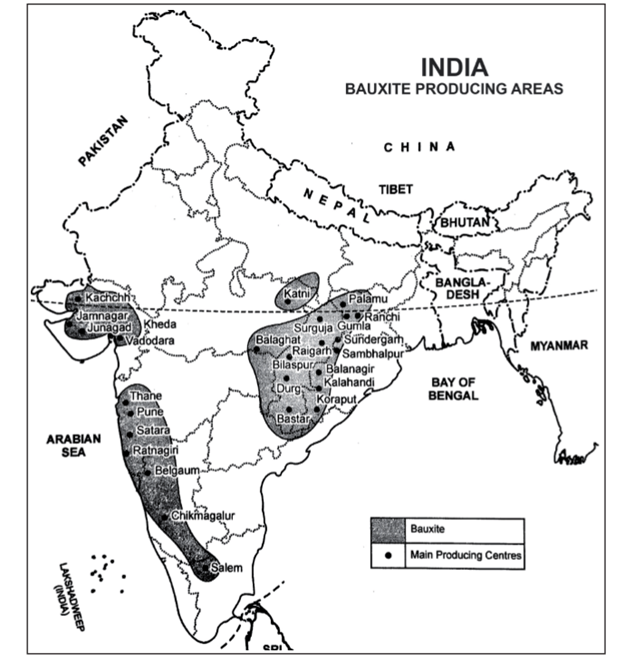

Bauxite

- Bauxite is an important ore which is used for making aluminium. It is an oxide of aluminium.

- It is not a specific mineral but a rock consisting mainly of hydrated aluminium oxides.

- It is a clay-like substance which is pinkish, whitish or reddish in colour depending on the amount of iron content.

Production and Distribution

Odisha

- Odisha is the largest bauxite producing state accounting for more than one-third of the total production of India.

- The main bauxite belt is in Kalahandi and Koraput districts and extends further into Andhra Pradesh. This 300 km long. 40 to 100 km wide and 950 to 1300 metre thick belt is the largest bauxite bearing region of the country.

- The main deposits occur in Kalahandi, Koraput, Sundargarh, Bolangir and Sambalpur districts.

- The important mining areas include Chandgiri, Baphalimoli Parbat, Kathakal, Manjimali, Pasenmali, Kunnumali, Kodingandi, Pottangi and Karalput in Kalahandi and Koraput districts

Chhattisgarh

- Chhattisgarh is the second largest producer of bauxite in India and produces more than 18 per cent bauxite of India.

- The Maikala range in Bilaspur, Durg districts and the Amarkantak plateau regions of Surguja, Raigarh and Bilaspur are some of the areas having rich deposits of bauxite.

Maharashtra

- Maharashtra accounts for over 15 percent of the total bauxite produced in India.

- The total recoverable reserves in the state have been estimated to be of the order of 87.7 million tonnes.

- The largest deposits occur in Kolhapur district capping the plateau basalts.

- Udgeri, Dhangarwadi,Radhanagari and Inderganj in Kolhapur district contain rich deposits with alumina content 52 to 89 percent.

- The other districts with considerable deposits are Thane, Ratnagiri, Satara and Pune.

Jharkhand

- Jharkhand is an important bauxite producing state of India accounting for over 14 per cent of the total production. The reserves of this state are found in extensive areas of Ranchi, Lohardaga, Palamu and Gumla districts. Some bauxite is also found in Dumka and Munger districts. High grade ore occurs in Lohardaga and adjoining areas.

Non-Metallic Minerals

- India also produces a large number of non-metallic minerals although only a few of them have assumed as much industrial and economic importance as is done by the metallic minerals.

- However, they are used in a large variety of industries; the major industries being cement, fertilizers, electricals, etc.

Mica

- Most important mica-bearing pegmatites occur in Andhra Pradesh, Bihar, Jharkhand, Maharashtra and Occurrences of mica pegmatites are also reported from Gujarat, Haryana, Karnataka, Kerala, Odisha, Tamil Nadu and West Bengal. The total resources of mica in the country are estimated at 5, 32,237 tonnes out of which 1, 90,741 tonnes are placed under reserves category and 3, 41,496 tonnes under remaining resources category. Andhra Pradesh leads with 41 per cent share in country’s total resources followed by Rajasthan (21 per cent), Odisha (20 per cent), Maharashtra (15 per cent), Bihar (2 per cent) and balance (less than 1 per cent) in Jharkhand.

- India has a near monopoly in the production of mica, producing about 60 per cent of world’s total production.

- About 95 per cent of India’s mica is found in just three states of Andhra Pradesh, Rajasthan and Jharkhand. Some mica is produced in Bihar also.

Limestone

- Limestone is associated with rocks composed of either calcium carbonate, the double carbonate of calcium and magnesium, or mixture of these two constituents. In addition to the main constituents of calcium and magnesium carbonates, limestone also contains small quantities of silica, alumina, iron oxides, phosphorus and sulphur. Limestone deposits are of sedimentary origin and exist in almost all the geological sequences from pre-cambrian to recent except in Gondwana.

- The total resources of limestone of all categories and grades are estimated at 2, 03,225 million tonnes in 2015. Karnataka is the leading state having 27 per cent of total resources followed by Andhra Pradesh and Rajasthan (12 per cent each), Gujarat (10 per cent), Meghalaya (9 per cent), Telangana (8 per cent) and Chhattisgarh (5 per cent). The total production of limestone was 293 million tonnes in 2014-15, an increase by 4% as compared to that of the previous year. As much as 87.22% of the total output in 201415 was contributed by eight principal states, viz., Rajasthan (21.02%), Madhya Pradesh (13.31%), Andhra Pradesh (12.10%), Gujarat (8.79%), Karnataka (8.21%), Telangana (8.18%), Chhattisgarh (8.03%) and Tamil Nadu (7.58%). The remaining 12.78% of the total production was shared by other limestone producing states.

- Limestone is used for a large variety of purposes. Of the total consumption, 75 per cent is used in cement industry, 16 per cent in iron and steel industry and 4 per cent in the chemical industries. Rest of the limestone is used in paper, sugar, fertilizers, glass, rubber and ferromanganese industries.

Diamonds

- Diamonds have been highly valued and cherished throughout the ages because of their brilliance, adamantine, lustre, transparency and hardness. They are widely used for ornaments and for polishing the surface metals, minerals and gem cutting.

- The most important industrial use of diamonds is in cutting- edges of drills used for exploration and mining of minerals. The production of diamonds had increased from 1,674 carats valued at 5.34 lakh in 1950 to 18,489 carats valued at 19.8 crore in 2011-12. The main diamond bearing areas are Panna belt in Madhya Pradesh; Wajrakarur Kimberlite pipe in Anantapur district and the gravels of the Krishna river basin in Andhra Pradesh.

- Reserves have been estimated only in Panna belt and Krishna Gravels in Andhra Pradesh. The total in situ reserves are about 26, 43,824 carats. There are conditional resources of 19, 36,512 carat. The new kimberlite fields are discovered recently in Raichur-Gulbarga districts of Karnataka.

- Further investigations for diamonds are being carried out in Andhra Pradesh, Madhya Pradesh and Karnataka. Reserves of diamonds in India are not yet exhausted and modern methods are being applied for intensive prospecting and mining in Panna, Kumool, Bellary and some other selected places in central India. Indian diamonds are in great demand in the international market, especially for jewellery.

- Cutting and polishing of diamonds is done by modern techniques at important centres like Surat, Navasari, and Ahmedabad. Palanpur, Bhavnagar and Mumbai. Khambhat, Jaipur, Trichur and Goa are comparatively new centres

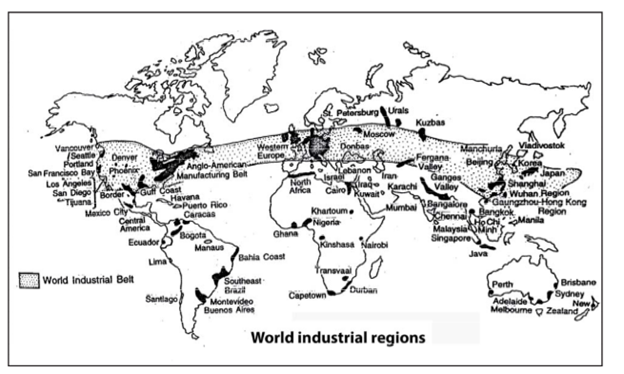

INDUSTRIAL REGIONS OF THE WORLD

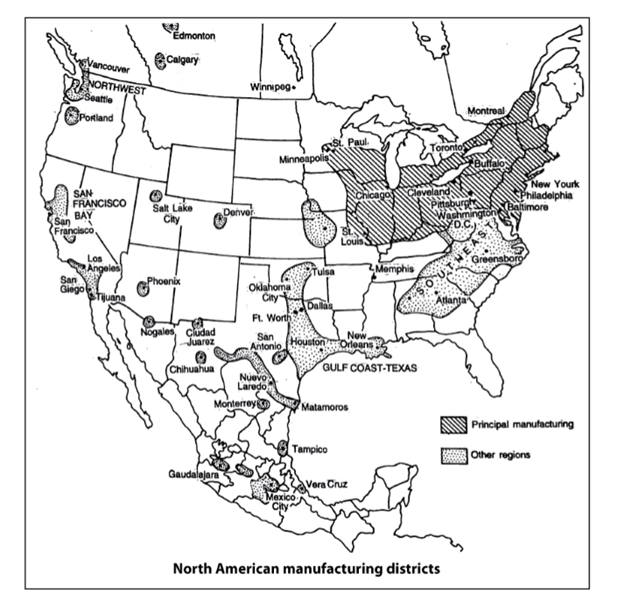

North American Region

About four-fifth of the industrial output in this region is contributed from United States of America. Another major industrial country is Canada.

United States of America

- USA is the most dominant industrial super-power in the world.

- The total contribution of industry in the national Gross Domestic Product (GDP) in 1995 was 31 per cent of the total i.e. $ 6,952,020 million. The value of Merchandise import and export in 1996 was $ 814,888 and $ 575,477, respectively.

- At least 26% of the population is directly or indirectly involved in manufacturing activities. The manufacturing activities are available almost in all states, though some regions have wider concentration of industries, particularly in the north-eastern states.

- It is, however, very difficult to delineate the boundaries of different industrial regions, because most of the regions are geographically inseparable.

- The industrial regions in USA may broadly fall into following regions:

- The New England Regions

- The New York-Mid-Atlantic Region

- The Mid-lake Region

- The North-Eastern Region

- The Southern industrial Region

- The Western Region

- The Pacific Region

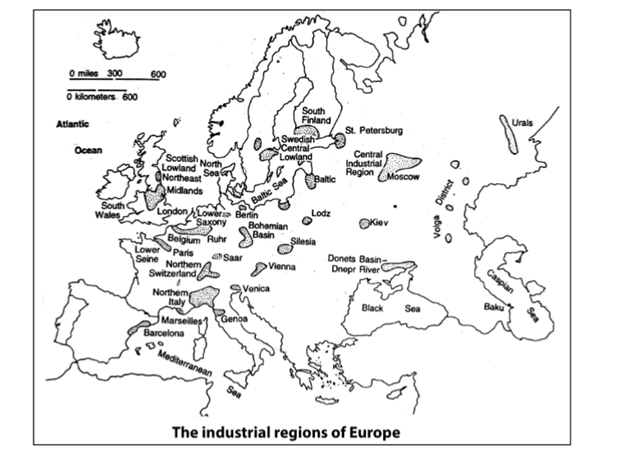

European Region

In Europe, particularly in Western Europe, most of the countries are highly industrialized. Some of the countries are leading manufacturing countries in the world. These are Germany, United Kingdom, Italy, France, Spain etc

United Kingdom

- United Kingdom is one of the most industrialized countries of the world. In fact, modern industrialization largely took its birth in British soil. In 1995, total industrial output in Britain was 32 per cent of the GDP.

- 29 per cent of the labour force is directly engaged in industry. Great Britain is having almost all types of manufacturing industries.

- The major manufacturing items are engineering, ferrous, chemical, textile, ceramic, electrical, leather, food and beverages and even electronics.

- The manufacturing region of Britain may be sub-divided into following groups:

- The Midland

- The Lower Scotland

- The North-East Coast

- The South Wales

- The Lancashire

- The London Basin

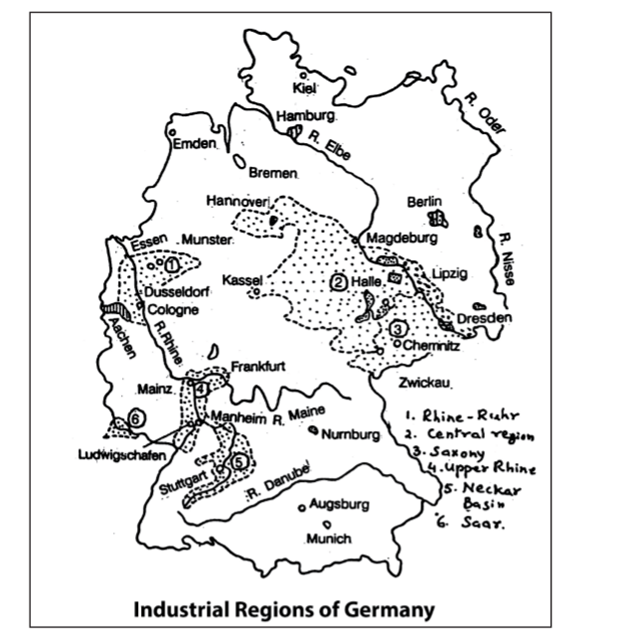

Germany

- The United Germany is one of the most dominant industrial powers in Europe. Even before unification, West Germany was considered as a great industrial power.

- In 1996, industry contributed 38.2 per cent of the total GDP About 38% people were engaged in manufacturing activities.

- The major manufacturing regions in Germany are:

- The Rhine Industrial Region

- The Saar and Middle Rhine Industrial Region

- The Hamburg Industrial Region

- The Berlin Industrial Region

- The Leipzig Industrial Region

CIS: Commonwealth of Independent States

- The CIS is one of the mighty industrial powers of the world. In 1995, industry contributed nearly 40 per cent of the gross national product in Russian Federation.

- Nearly 47 per cent of work forces in 1991 were engaged in manufacturing industry.

- Soviet industrial regions may be sub-divided into following regions:

- The Moscow-Tula Industrial Region

- The Southern Industrial Region

- The Caucasus Industrial Region

- The Ural Industrial Region

- The Volga Industrial Region

- The Kuznetsk Industrial Region

- The Central Asia Industrial Region

Asian Region

Until very recent period, no country in Asia had a sound industrial base. But, with the emergence of some countries like Japan, China, India, Korea, Taiwan in industrial sector, this region is now posing grave threat to the traditionally developed nations. In fact, regarding future industrialization of the world, Asia is frequently regarded as the dark horse.

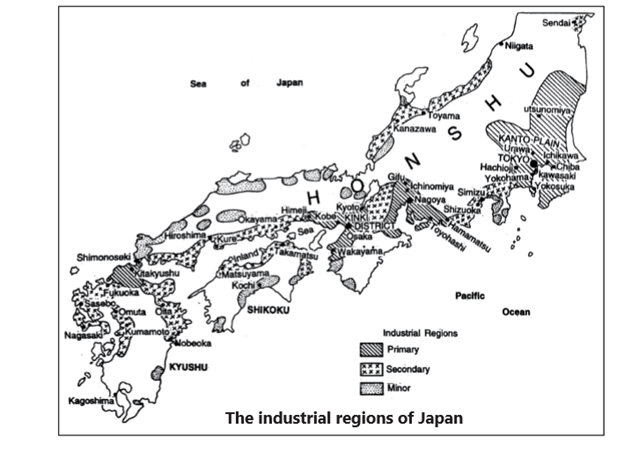

Japan

- The meteoric rise of Japan in the industrial scenario has shattered the long-established domination of European and North American countries. The output and efficiency of Japanese industry is now comparable with any other industrialized country in the world.

- Japan now dominates almost all key industries, ranging from heavy chemical, iron-steel, petro-chemical to Ferro-alloy, electrical, electronics, motor vehicles and other consumer products.

- At present, 35 per cent of the working people in Japan are engaged in manufacturing activities. In 1995, manufacturing in Japan contributed 38 per cent of the country’s GNP.

- Though Japanese industry had undergone a massive transformation, the spatial distribution pattern of industries remained unchanged. The intricate relationship between import of raw materials and export of finished products forced the industries to locate near coastal areas.

- The major industrial regions in Japan may be sub-divided into the following zones:

- The Tokyo-Yokohama Region

- The Osaka-Kobe Region

- The Chukyo Region

- The North Kyushu Region

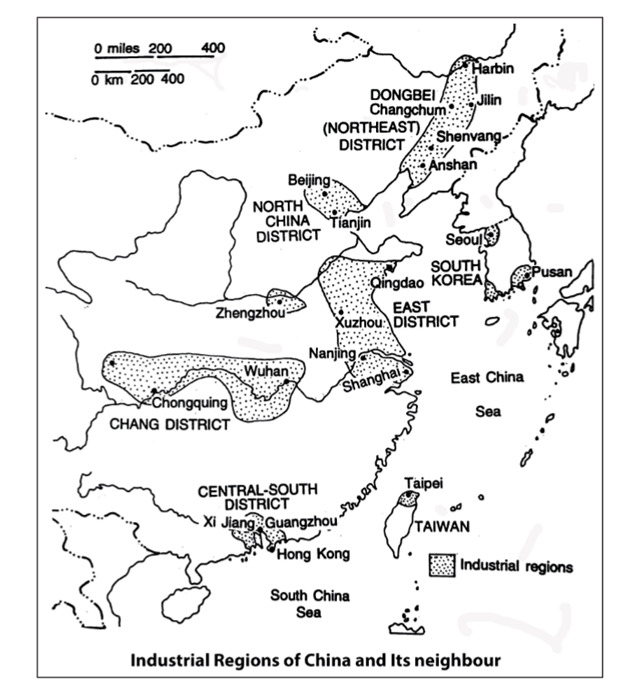

China

- China is gradually becoming one of the most dominant industrial powers in the world. In the year 1995, China produced 48 per cent of her GDP. from industrial sector. During this year, China handled the trade of merchandise product worth $ 138,833 million import and $ 151,047 million of export.

- The real development of industry in China began only after the installation of Communist rule in 1949.

- Chinese industrial system had gone through a complete transformation in last 50 years of Communist Rules. Old industrial policies were discarded and new policies were adopted. States power is supervising industrial development of the country in a planned manner. Eradication of regional imbalance and dispersion of the industries were encouraged. Basic industries like iron- steel, chemicals, textiles were given priority. On the basis of concentration of industries and their output, Chinese industrial regions may be sub-divided into following regions:

- The Manchuria Region

- The Yantze Valley Region

- The North China Region

- The South China Region

- Other Regions

India

- Since independence (1947), India has gradually emerged as a moderately industrialized nation. In some fields of manufacturing activity, Indian advancement is really spectacular. It is now considered as one of the leading industrialized country in the world. In 1995, industry contributed 29 per cent of the Gross Domestic Product.

- Spatially, Indian manufacturing establishments are mal-distributed. Some states are having very high concentration, while other regions are devoid of industries. It has been observed that regions situated in the plain, fertile lands and colonial heritage are historically having sound industrial base.

- Due to the failure of new centres to compete with old traditional centres, almost a status quo is maintained even today. Of late, some new industrial centres were evolved, specially around the steel cities.

- Among the states, Maharashtra contributes largest amount of industrial products, followed by Gujarat, Tamil Nadu, West Bengal, Uttar Pradesh, Bihar, Karnataka etc. According to the regional concentration of industries, Indian manufacturing regions may be sub-divided into six broad regions.

- India Industrial Regions

- The Calcutta Conurbation

- The Bombay-Poona Megalopolis

- The Ahmedabad-Vadodara Region

- The Southern Industrial Region

- The Damodar Valley Region

- The Capital Regions

The Calcutta Conurbation:

- Broadly, a narrow strip running from Banshberia and Naihati in the north to Budge Budge and Uluberia in the south along the river Hooghly may be taken as the demarcating line of this oldest and vast industrial region in India. Several suburban and satellite townships were developed within this region.

- Notable among these are Howrah, Liluah, Bally, Uttarpara, Hind Motor, Konnagar, Rishra, Srirampur, Chandannagar, Bandel, Uluberia in the western bank and Budge Budge, Birlapur, DumDum, Belghoria, Sodepur, Titagarh, Barrackpur, Shyamnagar, Naithati in the eastern bank of river Hoogly.

- The major industries located in this region are jute mills, cotton textiles, chemicals, drugs and pharmaceuticals, engineering, machine tools, automobiles, tobacco, food processing, leather, fabrication, paper, match, etc.

- Several factors proved to be advantageous for the growth of these industrial regions. These were:

- The port facilities of Calcutta

- Calcutta was then the seat of administration and capital of imperialist power

- Good transportation, through rail, road and water ways

- The proximity of the region towards mineral belts of Chotanagpur plateau

- Large market within Calcutta metropolis

- Extensive hinterland over eastern India

- Development of science and technology in renaissance period

- Cheap, available labour force from adjoining Bihar, Uttar Pradesh

- Entrepreneurial ability of the foreign and national bourgeoisie etc

The Bombay-Poona Megalopolis:

- This region stretches from Bombay metropolis to Poona in the south. Major industrial centres are Andheri, Belapur, Thane, Kalyan, Pimpri and Poona. The major manufacturing items produced here are: Textile, drugs and pharmaceuticals, chemical, petro-chemical, paper, leather, engineering, fertilizer and precision instruments.

- The major factors responsible for the growth of this industrial region were:

- Development and growth of Bombay port

- Development of communication system through rail and road

- Vast hinterland

- Managerial and entrepreneurship ability of Parsi, Bhatia people

- Huge capital from foreign and indigenous source

- Development of science and technology in the region

- Cheap power resources

- Cheap labour from Konakan and other regions etc

The Ahmedabad-Vadodara Region:

- Due to growing congestion and related problems, cotton textile industry gradually shifted from Bombay and grew in this region. Later on numerous other industries like petrochemical, chemical, fertilizer and engineering factories were evolved.

- The other centres of manufacturing industries are Bharuch, Surat etc. Exploration of petroleum in this region gives it a distinct advantage. This is one of the highly growing industrial regions in India.

The Southern Industrial Region:

- The extensive industrial region of South India is popularly known as Madras-Coimbatore-Bangalore region. This is also an old region. The major products of the region are textile, sugar, engineering, refinery, chemical, drugs and pharmaceuticals, automobiles, fertilizer etc.

- The reasons for the development of the region are:

- The facilities of export-import through Madras Port,

- Easy communication through rail and road,

- Large hinterland etc

The Damodar Valley Region:

- The mineral-rich area of Chotanagpur area is now one of the most developed industrial regions in India. The availability of local coal, iron ore, bauxite, limestone, manganese, mica and other minerals, attracted a large number of mineral based industries. Besides mineral, proximity to Calcutta market, cheap labour and high demand also facilitated the development.

- The major industrial areas are steel cities of Jamshedpur, Durgapur, Bokaro, Burnpur, Hirapur, Kulti, Asansol; coal centres like Raniganj, Jharia, Dhanbad and township Ranchi etc. Apart from iron-steel, heavy engineering, metallurgical, glass, ceramics, machine tools, alloy steel, agricultural machinery etc. are produced in this region.

The Capital Regions:

- Adjacent to the Delhi metropolitan area, several industrial establishments developed. This is the new industrial area, compared to the others. The major centres of production are Faridabad, Ghaziabad, Mathura, Saharanpur etc. The major products of the region are textile, engineering, leather, drugs and pharmaceuticals, petroleum refinery, toilet and cosmetic products, detergents etc.

International Dam Safety Conference

Context

- Central Water Commission in collaboration with Odisha Water Resources Department and World Bank has organized the International Dam Safety Conference in Bhubaneswar, Odisha.

About

More on news

- International Commission on Large Dams (ICOLD) and National Committees on Large Dams were among the organizing partners for this conference.

- Dam Safety Conferences are being organized as an annual event in different Dam Rehabilitation and Improvement Programme (DRIP) States in collaboration with the Implementing Agencies and leading academic institutes to provide a common platform for all stakeholders including non-DRIP States.

- Conference aims on deliberate all aspects related to dam safety and the solutions that worked best in addressing dam safety concerns.

Why is Dam rehabilitation and dam safety necessary?

- India ranks third globally with 5264 large dams in operation and about 437 are under construction. In addition, there are several thousand smaller dams.

- According to National Register of Large Dams (NRLD) maintained by Central Water Commission (CWC) 209 dams are 100 years or more old in India.

- Dams are vital for ensuring the water security of the country therefore constitute a major responsibility in terms of asset management and safety.

Dam Rehabilitation and Improvement Programme (DRIP)

- In 2012, Ministry of Water Resources, River Development & Ganga Rejuvenation embarked upon the six year DRIP with World Bank assistance.

- The objective was to improve safety and operational performance of selected dams, along with institutional strengthening with system wide management approach.

- The project originally envisaged the rehabilitation and improvement of 223 dam projects in four states namely, Kerala, Madhya Pradesh, Odisha, and Tamil Nadu.

- Later Karnataka, Uttarakhand (UJVNL) and Damodar Valley Corporation (DVC) joined the DRIP and presently 198 dam projects are being rehabilitated.

- DRIP has been successful in bringing together dam owners, engineers, scientists, academicians, industries, World Bank as well as renowned dam safety professionals.

- In addition to rehabilitation of dams, other important activities include activities such as development of Dam Health and Rehabilitation Monitoring Application (DHARMA) etc.

- It also developed Seismic Hazard Mapping along with development of Seismic Hazard Assessment Information System (SHAISYS).

- Under DRIP, capacity building in dam safety area of eleven academic institutions is being done.

- Also, capacity building of two Central Agencies i.e. Central Soil and Material Research Station (CSMRS) as well as Central Water and Power Research Station (CWPRS), is also one of the activities.

- Collaboration with few renowned international agencies for capacity building includes Deltares Netherlands, Bureau of Reclamation USA, and Japan Water Agency Japan, Entura.

- The overall supervision and coordination has been entrusted to Central Water Commission, and is being assisted by Egis Eau, Engineering and Management Consultant.

Shifting of North Magnetic Pole

Context

- Scientists have released a new World Magnetic Model (WMM) to represent the fast drifting of the magnetic North Pole, from the Canadian Arctic to Russia. Since 2000 the rate of moving has jumped from about nine miles (14.5km) to 34 miles (55km) a year.

- A new and updated version of the WMM is released every five years.

About

What are magnetic poles and how are they different from geographical poles?

- The magnetic North Pole, or South Pole, does not coincide with the geographical North or South Pole.

- Currently, the magnetic North Pole is located somewhere over northern Canada, a fact discovered in 1831 by Sir James Clark Ross.

- Earth behaves like a giant bar magnet characterized by its magnetic north and south poles, which are not static. A compass points towards magnetic north.

- The Earth’s magnetic behaviour is far more complex than that of a simple bar magnet. Its north poles and south poles move around sometimes erratically.

- Over large periods of time, they change their locations significantly, sometimes even interchanging their positions.

- The last time it so happened, with the magnetic North Pole getting somewhere near where the magnetic South Pole currently is, was about 780,000 years ago.

What is the source of magnetic field of earth?

- The origin of Earth’s magnetism lies in its outer core, a more than 2,000-km layer of liquid iron and some other metals like nickel that surrounds the central core, or the innermost part.

- This liquid iron is in constant motion due to Earth’s rotation and various other reasons, and this motion produces a magnetic field.

What causes the current shift?

- The movement of liquid iron and other metals in the outer core of the Earth is known to influence the magnetic field, but this movement is chaotic and turbulent. Though it has not been fully understood but scientists hope that this acceleration in the shifting of magnetic north pole would throw some new insights into the phenomena happening deep inside the Earth’s surface.

- The pole’s recent travels are believed to be caused by the formation of a narrow stream, much like the jet stream in the atmosphere, in the Earth’s liquid outer core.

- The iron-nickel core is so hot that it flows like water, 1,869 miles (3,000km) beneath the surface, creating the magnetic field and dragging it around the planet.

- The north magnetic pole has been caught up in this jet and it’s pushing it rapidly across to Siberia.

- The south magnetic pole is moving far more slowly than the north, because the liquid outer core is moving differently in the southern hemisphere.

Does it mean stronger magnetic field for earth at present?

- Earth’s magnetic field is growing steadily weaker, leading scientists to think it will eventually flip, with the north and south poles changing places like a bar magnet flipping over.

- Researchers know from traces left in rocks that this has happened before, but not in the past 780,000 years.

- Magnetic field’s movement, and the rise and fall in its strength, are all part of its natural behaviour.

- In the long term, the movement of the north magnetic field could become noticeable because it affects where aurora, such as the northern lights, can be seen.

- The aurora is centred on the north magnetic pole in a ring, so as the pole moves, the aurora will follow it.

What are the uses of World Magnetic Model?

- Accurate readings of the magnetic north pole by the WMM are vital for military, surveying and mapping, satellite/antenna tracking, undersea and aircraft navigation, airlines, search-and-rescue operations and other projects circling the North Pole.

- Smartphone and consumer electronics companies also rely on the WMM to provide consumers with accurate compass apps, maps, and GPS services.

1st International Conference on “Landslides Risk Reduction and Resilience-2019”

Context

The Union Minister of State for Home Affairs inaugurated the 1st International Conference on “Landslides Risk Reduction and Resilience” in Delhi. The conference has been organised by the National Institute of Disaster Management.

About

- The conference has been organised by the National Institute of Disaster Management.

- Aim of the Conference is to explore and debate the most recent advances in landslide risk reduction and resilience.

- Continent-wise, Asia suffers the maximum damages / losses due to landslides and among the Asian countries, South Asian nations are the worst sufferers and even among South Asian countries India is one of the worse affected by landslides.

- As landslides are frequent and widespread, the annual cumulative losses worldwide amount to tens of billions of USD in terms of lost property, environmental damage, repair works, and the maintenance of defence measures.

- As per Geological Survey of India, the window of economic loss due to landslides may reach between 1-2% of the gross national product in many developing countries.

OBJECTIVES

The aim of Conference is to explore and debate the most recent advances in a discipline. This will be directed towards understanding past and present processes and through different approaches involve in landslide risk reduction and resilience with the following objectives:

- To enhance the understanding of the issues and solutions on governance and administration for landslides risk reduction and resilience

- To discuss about current practices in the landslides risk assessment, mitigation and monitoring technologies for landslide risks and resilience with case examples

- To highlight the environmental and emerging issues in context with urbanization, development and climate change

- To share experiences related to community based landslides risk reduction and resilience

- To disseminate information related to national and local strategies for landslides risk reduction and resilience as well as to develop a network mode roadmap for addressing the gaps by engaging with the institutions, researchers and experts.

SPECIAL FOCUS IS GIVEN TO:

- Governance and administrative issues and support for LRR&R

- Tools, techniques and technologies for LRR&R

- Impact of climatic change, development, urbanization, and population growth for LRR&R

India State of Forest Report (ISFR) on density of forest

_on_density_of_forest-min.jpg )

Ban on Single-Use Plastic

Global Coalition to Protect Pollinators

Emissions Trading Scheme (ETS)

-min.jpg)

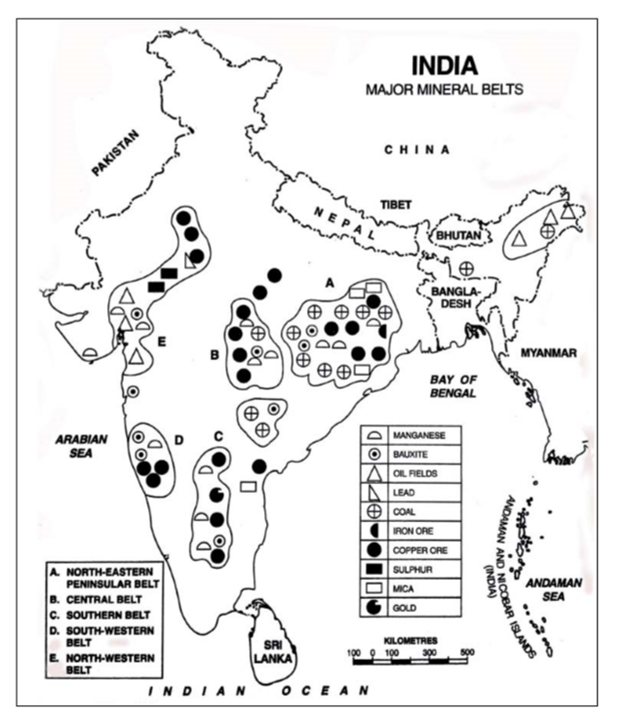

India Water Week-2019