11th April 2022 (6 Topics)

Context

Global automakers, mining corporations, and investors are investing millions of dollars in direct lithium extraction firms, wagering that they will supply the majority of the lithium required to fuel the electric car revolution.

About New Technology:

- Miners will be able to increase worldwide lithium output with a far smaller footprint than open-pit mining and evaporation ponds, which are frequently the size of several football fields & unpopular with local residents.

- These so-called direct lithium extraction (DLE) methods extract the white metal from brine via filters, membranes, ceramic beads, or other equipment that can usually be housed in a small warehouse.

- However, they frequently require large amounts of potable water and energy, and none have been tested on a commercial scale.

- DLE technology would compete with existing miners like Albemarle Corp, the world's largest lithium producer, as well as emerging miners like Lithium Americas Corp, pioneer Ltd, and Piedmont Lithium Inc.

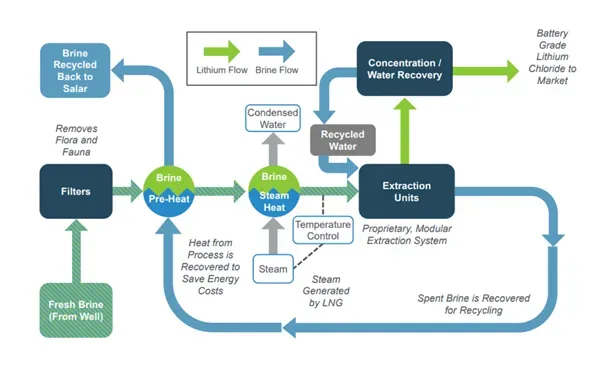

Direct Lithium Extraction Process:

- Direct Lithium Extraction extracts lithium from brine water via a highly selective absorbent.

- The solution collected from the brine water is then purified to produce high-quality Lithium Carbonate and Lithium Hydroxide.

- Direct Lithium Extraction differs from previous processes in that it eliminates key contaminants, resulting in a higher-quality output.

The key advantages include:

- Faster lithium production (hours/days rather than a year with evaporation ponds).

- Much less environmental impact because there is no need for a large area of evaporation ponds, resulting in a more acceptable ESG profile. Not weather-dependent.

- Not weather dependent.

- Reduced water use (the brine is returned to the Salar after lithium extraction).

- The potential to make low-grade lithium operations economically feasible. Up to 99% lithium recovery (often 70-90%), compared to ~40% for current processes.

- Can possibly create a better purity battery grade lithium end product that sells for a greater price than lesser grades.

The key disadvantages include:

- Not yet tried on a wide scale or for an extended period of time. This means that the long-term economics and efficacy remain to be determined.

- Technical difficulty - There are several DLE options available, as well as dangers associated with newer technologies.

- Depending on the project, the initial capex may be larger, as may the recurring capex. This is determined by a variety of parameters (location, DLE process type, energy cost, any valuable byproducts, geothermal advantages, etc.).

More Articles