Context

Biomass-based electricity is gaining attention of regulators and policy makers, as the country moves towards power generation that is not carbon-intensive.

About

- The Union Ministry of New and Renewable Energy (MNRE) announced central finance assistance for projects utilising biomass like bagasse, agro-based industrial residue, crop residues, wood produced through energy plantations, weeds as well as wood waste produced in industrial operations for power generation.

- According to Union Power Ministry, Around 2.6 per cent of the country’s electricity demand is met by biomass.

About new Technology:

- Use of biomass to fire steam boilers at electricity generation units is also increasing to produce cleaner power.

- But these boilers are designed only for specific types of agro residue such as paddy husk, paddy straw, mustard, among others to be fired for its lifetime.

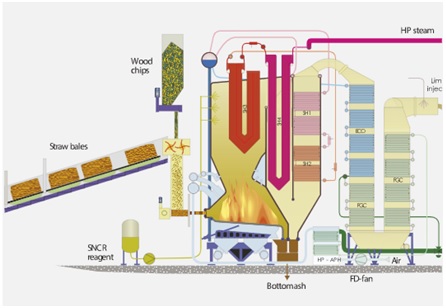

- A vibrating grate boiler launched recently in Denmark can be a solution for firing any kind of biomass. These boilers have a capacity of 75 tonnes per hour.

- The new Denmark-based technology allows the plant to fire a wide range of fuels with less fuel preparation and handling, and mainly avoid the energy-intensive process of briquetting and pelletisation.

Advantages:

- The new Denmark-combustion technology is advantageous because of the vibrating grate.

- The grate of a steam boiler supports the solid fuel in the furnace.

- It is so designed that it can also allow air to admit air in the solid fuel for combustion.

- Vibrating grate is different from the more common stationary, travelling and reciprocating grates since it accommodates biomass of every density.

- The moisture content of the fuel, however, has to be 15-20 per cent.

- Since the vibrating grate supports firing agro residue of any size, it saves energy consumed for processing biomass for energy generation

How it works?

- Instead of converting biomass into pellets or briquettes, the agro residue is converted into bales right after procurement from the farmers.

- Before it is conveyed to the combustion system, it is subjected to a bale string cutter and dosing screw to cut the string tying the bales and mixing the bales to reduce its size respectively.

- The size of the bale is reduced for achieving complete combustion of the biomass fed into the boiler.

- Then, the bales are sent to a vibrating grate for combustion.

- Here, the combustion happens as a series of events.

- For the first 250 seconds, a set of fuel is fired, and then it is moved to the next combustion stage by vibration.

- After the first set of biomass is moved to the next grate, fresh biomass enters the firing system for combustion.

- After complete combustion, the burnt biomass in the form of ash is let out for disposal.

- The biomass-based boiler is as efficient as a coal-based boiler.

- The average steam to fuel ratio of this biomass-fired boiler is 4-4.5 and the efficiency is also achieved upto 85 per cent, which is equivalent to coal-based thermal power generation.

- The average steam to fuel ratio of this biomass-fired boiler is 4-4.5 and the efficiency is also achieved upto 85 per cent, which is equivalent to coal-based thermal power generation.