27th September 2022 (7 Topics)

Context

The President of India, Droupadi Murmu inaugurated Hindustan Aeronautics Limited’s (HAL’s) state-of-the-art Integrated Cryogenic Engine Manufacturing Facility (ICMF) in Bengaluru recently.

About

About Integrated Cryogenic Engine Manufacturing Facility (ICMF):

- The state-of-the-art ICMF, set up over an area of 4,500 square metres houses over 70 hi-tech equipment and testing facilities for manufacturing cryogenic (CE20) and semi-cryogenic (SE2000) engines of Indian rockets.

- In 2013, an MOU was signed with ISRO for establishing the facility for manufacturing cryogenic engine modules at HAL, Aerospace Division, and it was subsequently amended in 2016 for setting up of ICMF with an investment of Rs 208 crore.

- ICMF will boost self-reliance in manufacturing of High-thrust Rocket engines.

- The facility will cater to the entire Rocket Engine Manufacturing under one roof for Indian Space Research Organisation (ISRO).

- HAL Aerospace Division manufactures liquid propellant tanks and launch vehicle structures of Polar Satellite Launch Vehicle (PSLV), Geosynchronous Satellite Launch Vehicle (GSLV MK-II), GSLV Mk-III and also stage integration for GSLV MK-II.

- The Aerospace Division entering into manufacture of Cryogenic Engines is a major step in technology up-gradation cum modernization.

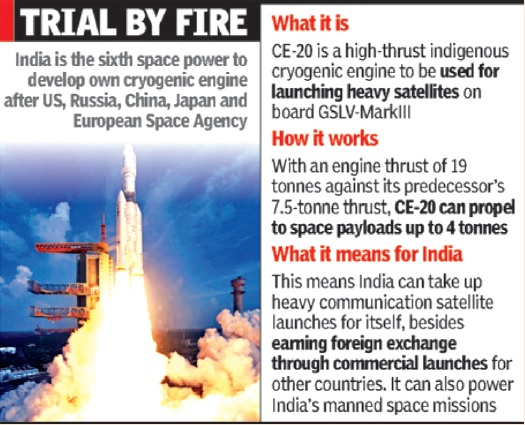

- Indigenous cryogenic technology is important as it will assist India to further develop its rocket programme for launching heavy satellites.

Cryogenic Engine:

- A cryogenic rocket engine is a rocket engine that uses a cryogenic fuel or oxidizer, that is, its fuel or oxidizers (or both) are gases liquefied and stored at very low temperatures.

- Due to use of liquid gases as propellants, the cryogenic Rocket Engines are also called liquid-propellant rocket engines.

- The engine uses cryogenic propellants i.e., Liquid Hydrogen at -265°C as fuel and Liquid O2 at -240° C as oxidizer.

- The major components of a cryogenic rocket engine are the combustion chamber (thrust chamber), pyrotechnic initiator, fuel injector, fuel cryopumps, oxidizer cryopumps, gas turbine, cryo valves, regulators, the fuel tanks, and rocket engine nozzle.

- In terms of feeding propellants to the combustion chamber, cryogenic rocket engines are either pressure-fed or pump-fed, and pump-fed engines work in either a gas-generator cycle, a staged-combustion cycle, or an expander cycle.

Advantages:

- High Energy per unit mass: Propellants like oxygen and hydrogen in liquid form give very high amounts of energy per unit mass due to which the amount of fuel to be carried aboard the rockets decreases.

- Clean Fuels: Hydrogen and oxygen are extremely clean fuels. When they combine, they give out only water. This water is thrown out of the nozzle in form of very hot vapor. Thus the rocket is nothing but a high burning steam engine.

- Cryogenic rocket engines are much efficient than solid propellant based engines. They can deliver more thrust for a given mass of propellant.

- The cryogenics are also essential requirements for the manned space flight ISRO’s is planning to launch in the near future.

- The lower weight of the cryogenic propellants makes it possible to carry additional payloads to longer distance. Only the US, Russia, China, France and Japan have had this technology so far.

Disadvantages:

- The fuel tanks tend to be bulky and require heavy insulation to store the propellant. Their high fuel efficiency, however, outweighs this disadvantage.

- Despite non-toxic tendencies, cryogenic fuels are denser than air. As such, they can lead to asphyxiation.

More Articles