5th May 2022 (6 Topics)

Context

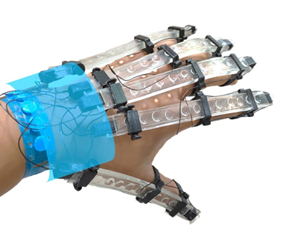

Researchers at Indian Institute of Science (IISc.) have developed customisable, 3D printed gloves can be remotely controlled, opening up the possibility of tele-consultation by physiotherapists.

About

Need:

- According to the researchers, stroke is India’s third leading cause of death, and the sixth leading cause of disability.

- Physiotherapy is one of the few treatments available for?rehabilitating stroke victims?and patients with physical injuries, but it can take days to months depending on the severity of the disability, making it challenging for patients as well as their attendants.

- Physiotherapy often requires daily hospital visits.

- Home visits by professionals or sophisticated devices to monitor patients remotely, although ideal, are not readily available, and are expensive.

- To address these challenges, the team developed a mechanism by which customisable wearables, like hand gloves, can be designed, 3D printed, and controlled remotely.

How it will help?

- The researchers used a silicon-based polymer material that is transparent (facilitating manipulation of light), soft (for comfort and repeated use), and most importantly, 3D printed.

- It can be customised to fit each patient’s arm and fingers.

- The device can capture and store data, and transmit it over the internet, facilitating remote monitoring by clinicians or physiotherapists.

Technology used:

- The technology that drives the device is based on the fundamental properties of light: refraction and reflection.

- A light source is placed at one end of a transparent rubbery material, and the other end has a light detector.

- Any movement in the finger or arm of the patient causes the flexible material to deform.

- The deformation alters the path of light and thereby its properties.

- The device translates this change in light properties to a quantifiable unit.

- Since light travels across the entire length of the device, movement along any part of the patient’s finger or arm can be accurately measured.

|

About 3D Printing:

|